What is QbD?

Quality by Design (QbD) is a design approach with a focus on building quality into the original product. A product can be defined as a good, service, information, or an internal process. The QbD process is organized into five major steps: defining the objectives and goals, the discovery of appropriate data, design, development, and delivery of a quality product.*

Traditional product development follows a linear approach; one person or team finishes a step in the project and then passes it off to the next person or team, and so on. QbD adheres to a more integrated process involving multiple teams working collaboratively for a more holistic, efficient, and quality-focused production (more checks and balances, etc.).

Traditional product development follows a linear approach; one person or team finishes a step in the project and then passes it off to the next person or team, and so on. QbD adheres to a more integrated process involving multiple teams working collaboratively for a more holistic, efficient, and quality-focused production (more checks and balances, etc.).

Ceres and QbD

As a turnkey solution to optimal grow-environments, we have adapted the guidelines of QbD to our design process. We believe building a better product, service, or system starts with defining the appropriate goals and carries through to the delivery of the end product. Every step of our process is thoughtfully designed for maximum quality and client satisfaction.

Beyond just the greenhouse structure, we provide a complete grow solution, working with our partners to supply and integrate all necessary equipment. We also do all Mechanical, Electrical, and Plumbing engineering, ensuring that the facility functions as a single unit (as opposed to many individual parts).

How Does Ceres apply principles of QbD?

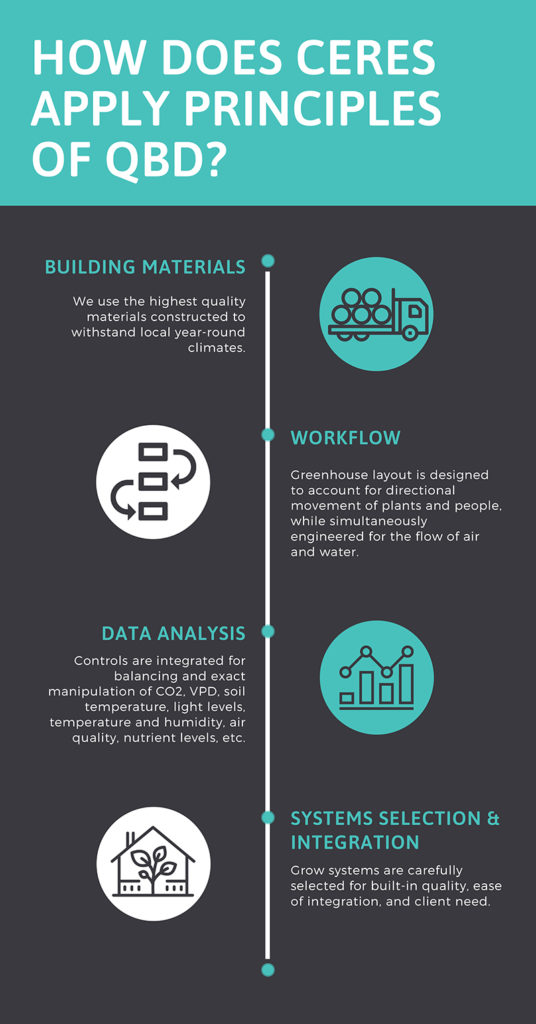

Building Materials

We use the highest quality materials constructed to withstand local year-round climates.

Workflow

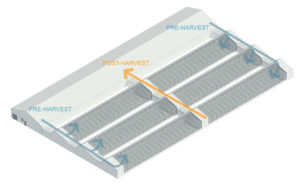

Greenhouse layout is designed to account for directional movement of plants and people, while simultaneously engineered for the flow of air and water.

Data Analysis

Controls are integrated for manipulation of CO2, VPD, soil temperature, light levels, temperature and humidity, air quality, nutrient levels, etc.

Systems Selection & Integration

Grow systems are carefully selected for built-in quality, ease of integration, and client need.

QbD Design Considerations

Designing for the highest quality system is not just about the integrity of the material (of course integrity IS important). Principles of QbD also involve designing for biosecurity, employee workflow, environmental consistency, measurability, and manufacturing efficiency.

Biosecurity

A QbD sealed greenhouse is biosecure. If it is sealed, outside threats like weather, pests, fungi, or mold cannot enter the grow environment.

Employee Workflow

Process flow is a less obvious but vital part of the design. How workers move within the facility will ensure greater efficiency and a cleaner, more consistent product.

Environmental Consistency

The grow environment must retain a consistent climate for efficiency and quality in production, as well as reducing the risk of unwanted pests.

Measurability

The ability to measure the final product is paramount to understanding quality in the product. Even before the product is finished, controls in the environment allow for continuous measurements and adjustments.

Manufacturing Efficiency

If the resultant product (plant) is high quality and consistent it can then move into manufacturing (if that is part of the client’s business goals) with greater efficiency.

What Are The Advantages Of Qbd?

Product Consistency

Variable and inconsistent products are hard to move into manufacturing, processing, or sales. Buyers develop expectations for the products they buy. Consistency is a must for client satisfaction and business forecasting.

Risk Management / Minimal Crop Failure

Designing with QbD principles ensures a degree of risk management. The entire design, flow, and production are conducted holistically with careful consideration to cleanliness, air and water quality, and product quality. Under QbD guidelines the chance of crop failure is dramatically reduced.

Effective Control of Change

Need to change something in your grow system? In your process? Whatever the change might be, making the change is possible when everything in your grow environment is tightly controlled.

Return on Investment / Cost Savings

Sensors, controllers, and efficient directional control are just a few things that enable low operational costs and potentially enormous cost savings.

Supports GMP Principles

Good Manufacturing Practices are a system of principles that define quality standards to which products must be produced. While GMP has traditionally referred to manufacturing and product standards, GMP principles are derived from a similar foundation as QbD principles.

We Choose QbD

We abide by the principles of Quality by Design because we believe that smartly designed products, systems, and processes create better, more efficient, cost-saving results. Plus, a better greenhouse means a more successful client.

*https://www.juran.com/blog/quality-by-design-qbd-an-overview/

For more information on how movement takes place inside the greenhouse, download our QBD below.