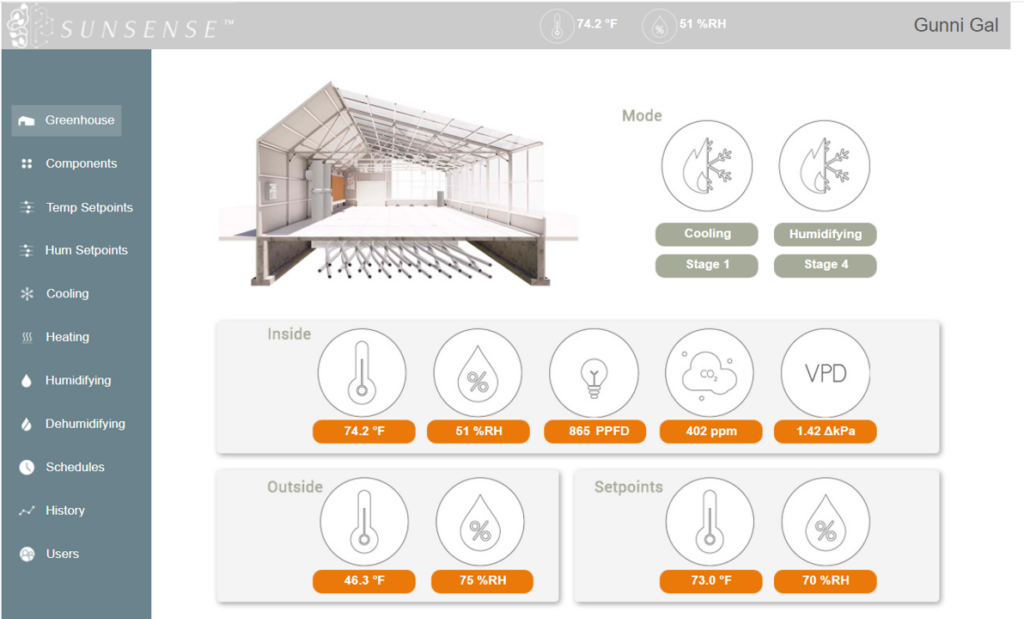

SunSense™ Controller

The SunSense™ controller enables growers to lower operating costs, improve quality, and increase yields. Optimized to work with our greenhouses and SunChamber™ systems, the Ceres SunSense™ is a holistic management tool for all environmental parameters, customizable to individual photosynthetic recipes.

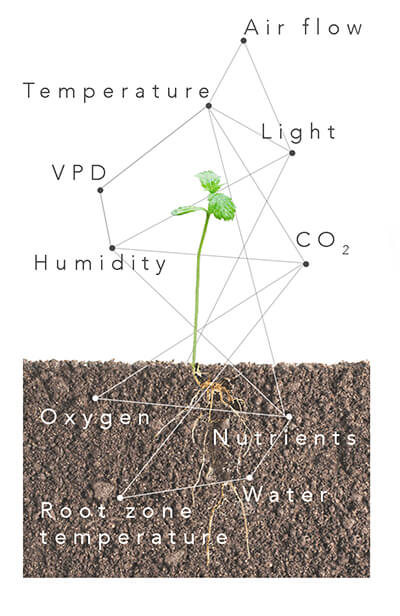

Designed around Plants

Environmental parameters are optimized for the plants, with customizable environmental recipes for individual strains at each stage of growth. Vapor Pressure Deficit (VPD) is specified by the grower and maintained by HVACD system.

SunSense™ Controller Capabilities:

Measures: Temperature, Relative humidity, CO2, PAR (light), Outdoor Climate, Leaf Temperature, Water Flow & Usage, Power Usage

Controls: Exhaust fans, Evaporative coolers, Airflow, On/Off & dimmable lighting, CO2 supplementation, HVAC & Dehumidification, Irrigation

Controlled Environment = Reduced risk of pests and disease

Engineered for Security & Expansion

- Modular design allows for continuous facility expansion

- Hardware and hardwired connections ensures data transmission in all environments

- Integrated data privacy and network security

- Secure and accessible data, with local and cloud storage

Built to Save Money

- SunSense™ reduces electrical infrastructure by eliminating nonessential loads during power outages

- Shifts electrical loads to avoid peak utility rates

- Minimizes HVACD and lighting energy consumption

- Monitors water consumption for reduced water and nutrient use

The Ceres Controller Increases Profits By:

- Maintaining VPD to minimize pest and pathogen outbreaks

- Optimizing the environment for higher yields

- Customizing the environment for each strain

- Documenting R&D to optimize new processes

The Ceres Controller Saves:

- 30% of all electrical installation & parts from emergency control

- 30% of energy use in the first year from load shifting

- Labor costs from reduced labor needs

- Fossil fuel usage

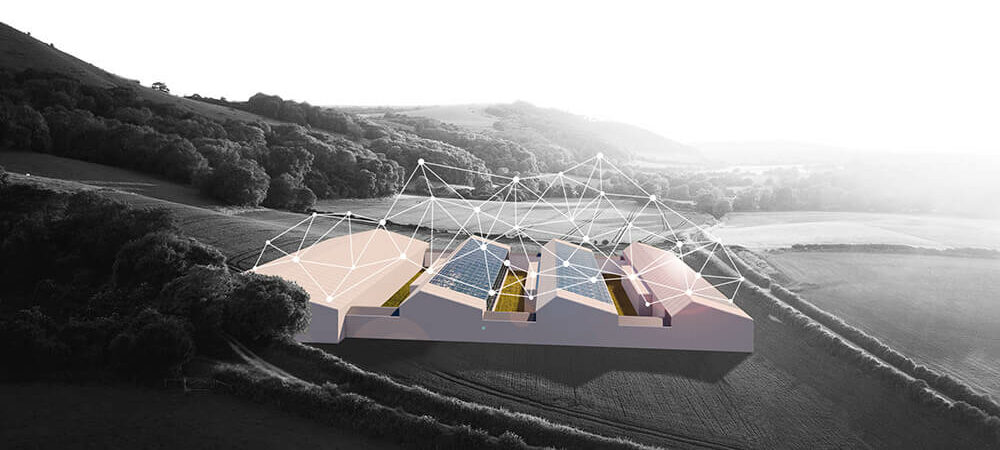

Greenhouse Technology

Supplemental lighting is required to optimize plant growth, plant quality and ultimately profits in low light conditions such as mornings/evenings, winter days with low light levels, and cloudy days.

One centralized system for controlling the whole environment. Monitor temperature, relative humidity, and CO2, leaf/ canopy temp, PAR, lighting zones, and outdoor weather.

Unlike most other grow facilities, at Ceres we integrate a water recapture & filtration system in every greenhouse, Recapture and filtration not only increase efficiency, it also saves money, especially in places where water is scarce.

Grow the highest quality crop with full UV transmission. ETFE is durable and easy to repair. It allows all of the benefits of an outdoor grow, while still maintaining complete environmental control with in the facility.

Ceres fully automated light deprivation greenhouses allow for total control of light levels in your commercial or medical cannabis facility. Light deprivation is a necessary component of an automated cannabis greenhouse and is available in every size and model.

Explore our proprietary HVAC, dehumidification, and humidification (fogging) systems. We offer everything from a la carte systems for retrofits, to fully integrated geothermal HVAC solutions for new builds. Learn more about our GAHT®, EcoLoop™, and EcoPack™ system options.

Access Cannabis Brochures

Calculate Your Energy Savings

Find out how much you can save with Ceres Greenhouses compared to standard greenhouses.

Related Webinars, Videos and Content

SunSense™ FAQs

Yes. We offer a few different options for a vented greenhouse. Please contact us for more information.

Yes. Contact us for more information.

Yes, the SunSense™ system can monitor and control CO2 levels in the greenhouse. All of our controllers monitor CO2 and can dose in real time based on the CO2 concentration in the greenhouse or other grow rooms.

In the application where supplemental CO2 is provided, Ceres can provide a third-party CO2 life safety package with all horns, strobes, and signage required by regulation to warn buildings occupants. In case of critical CO2 concentration, this system will initiate automated venting until the CO2 concentration is back in the safe concentration range.

The customer owns their data forever. However, we do require access to it for facility optimization. Data sets will not be shared with or viewed by other customers.

Data is stored on-site and in the cloud for remote access at any time. This will protect from loss of data. For more information on the use of data, please see the data analysis FAQ.

The dashboard allows the owner to set levels of access to employees, so you control who sees your data and who can control the facility.

Data can be accessed via our data analytics dashboard. From there, the customer can see all historical data from each sensor, equipment run times and operational modes, power consumption, etc.

The dashboard shows the details of your facility operations. This includes live sensor data, current operational modes of all of your equipment, along with any control inputs required for operation, user control, and alarms. The data analytics dashboard shows historical trends for all sensors and equipment in the facility, as well as power consumption breakdowns to understand operational efficiency.

The dashboard’s pictures and equipment will be customized to your facility, but we do not change the overall format/layout of our dashboard.