Cannabis Data Analysis

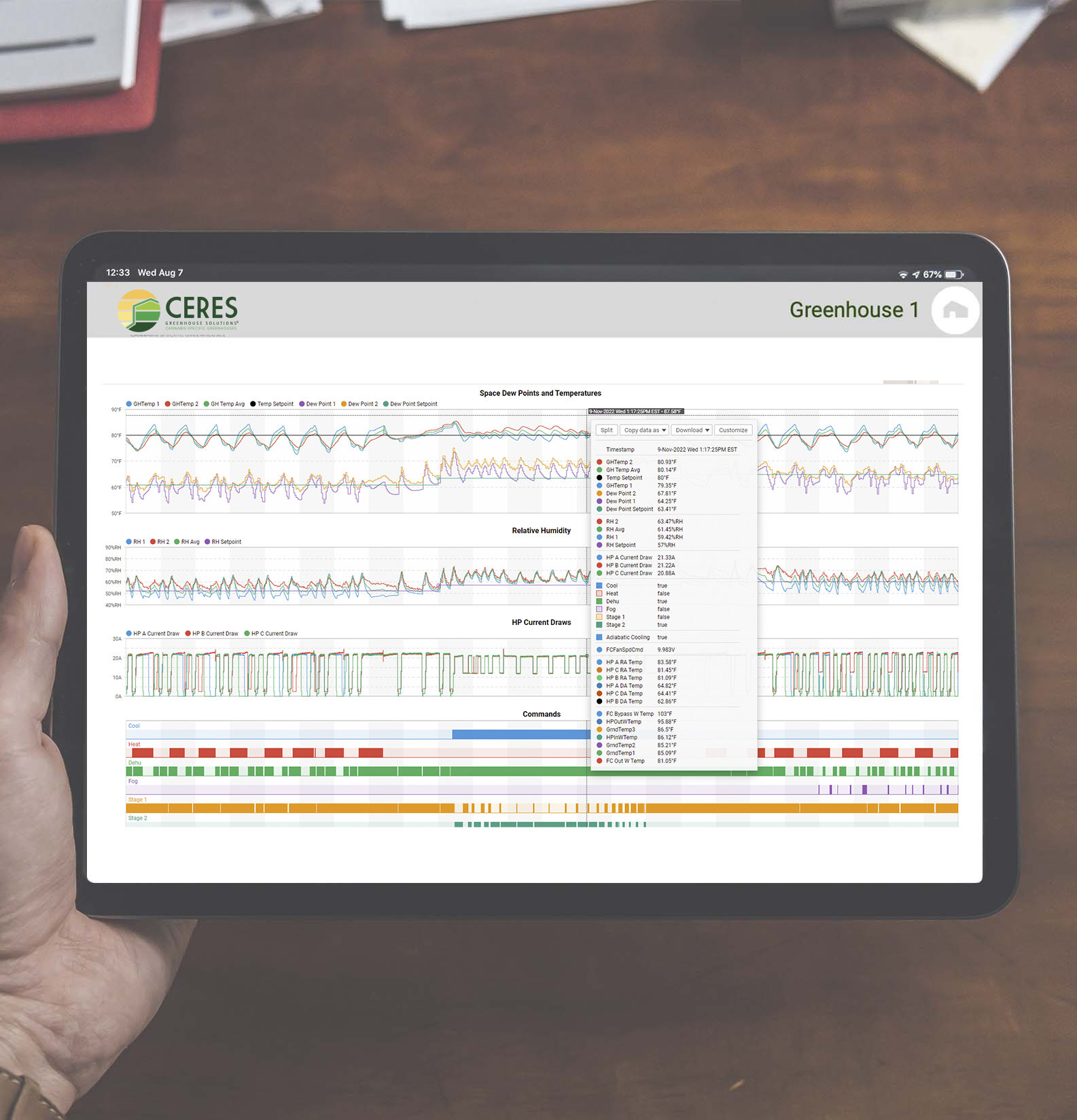

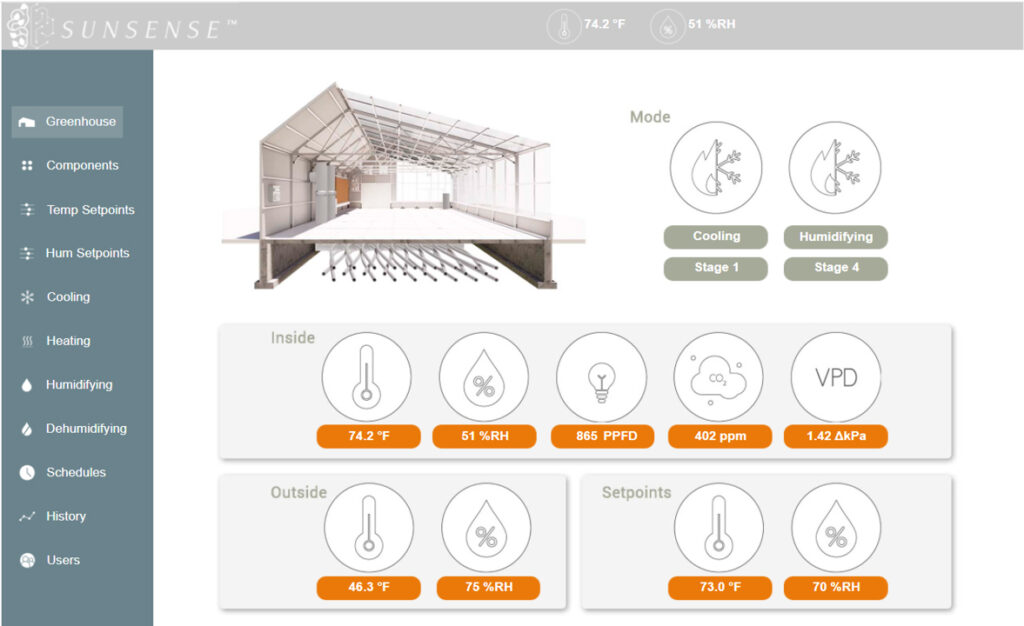

Achieve optimal efficiency and the highest quality crop output by pairing a Ceres SunSense™ controller with our experts in cannabis greenhouse data analysis. We understand that success is an ongoing process, which is why we work with our clients from project conception through production.

We are here to help troubleshoot any grow or environmental problems for all Ceres greenhouses, all while continuously optimizing your greenhouse environment, in order to ensure a higher quality product.

Cannabis Grow Support & Data Analysis Services

- Real-time monitoring of entire facility parameters:

- Environmental conditions through entire plant life-cycle

- Greenhouse and headhouse systems (HVACD, lights, fertigation, humidification, etc.)

- We create and analyze relevant KPIs to allow for continuous improvements.

- We provide customized recommendations will be made based on multiple parameters such as specific strains, time of year, location, growers requirements

SunSense™ Data Management Plans:

Ceres Data Analysis Base Plan

- Unlimited data storage to the cloud server and access to the SaaS dashboard

- 3 hours/year of support (a safety net for troubleshooting problems and calls)

Ceres Data Analysis Premium Plan

- Unlimited data storage to the cloud server and access to the SaaS dashboard

- 24 hours/year of support

A Typical Ceres Data Package Cadence: Ceres will analyze your data in preparation for a monthly meeting with your team where we will explain the trends we see and make recommendations on how to change your sequence of operations. Once agreed upon, we will make the changes and push the software to your system. This cadence is tailored to fit your team’s availability and needs.

What are we looking for?: Seasonal changes to operation, new control algorithms specific to the client, adding equipment/sensors, energy optimization, etc.

Ceres Greenhouse Services

Related Webinars, Videos and Content

Data Analysis

The Ceres Data Package cadence typically looks as follows: Our data team will analyze your data in preparation for a monthly meeting with your team where we will explain the trends we see and make recommendations on how to change your sequence of operations. Once agreed upon, we will make the changes and push the software to your system. This cadence is tailored to fit your team’s availability and needs.

Some of the unique advantages over a conventional geothermal system are the system’s resilience, redundancy, modularity, heating and cooling load capacities, and its low environmental impact. Additionally, the EcoLoop™ system requires minimal invasiveness to the earth (the system sits 6′ below grade, opposed to the 400′ bore holes of traditional vertical geothermal systems).

Contact us to learn more.