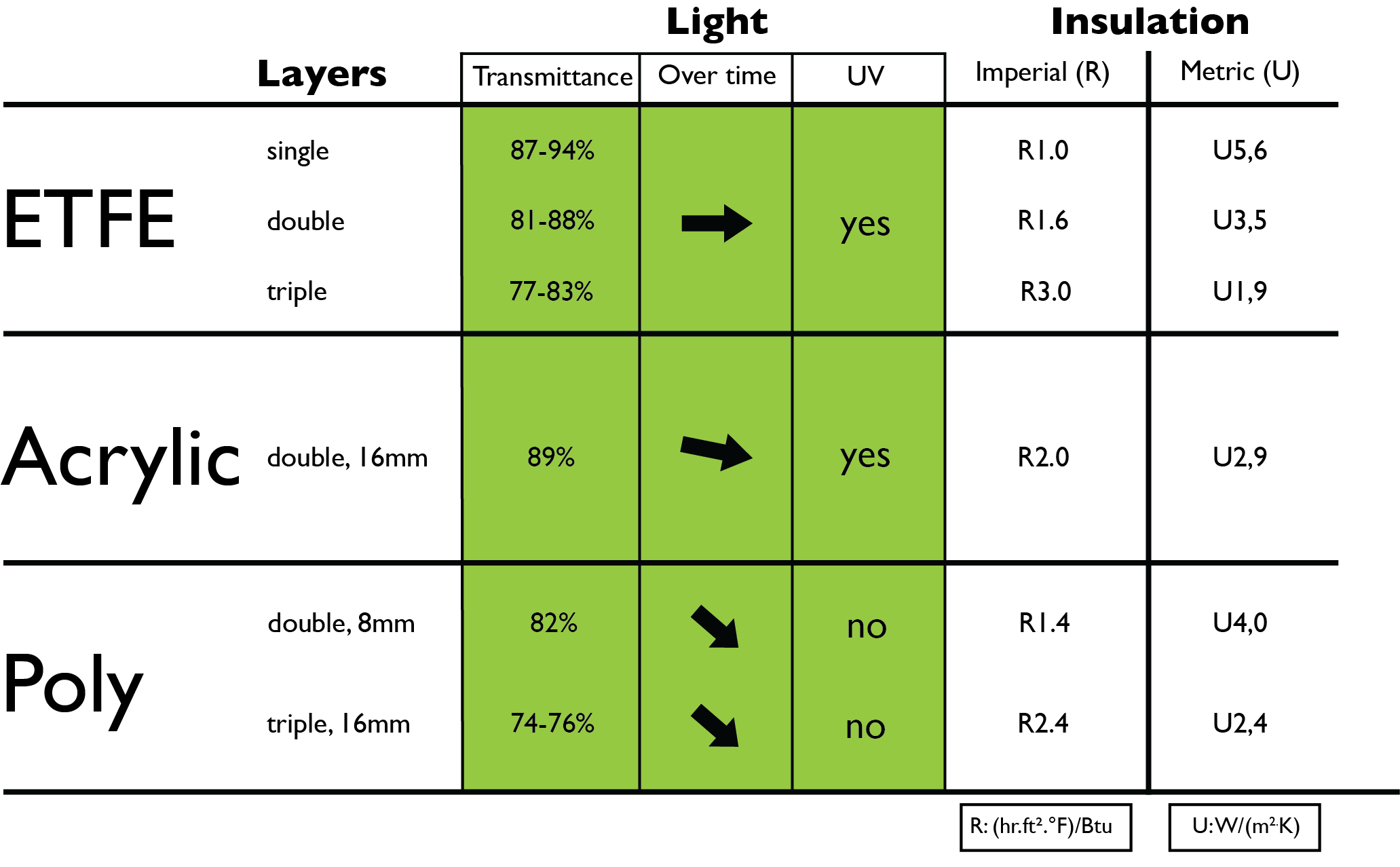

ETFE Glazing

ETFE has extremely high light transmission, durability, and resistance to hail–enabling the highest quality crop production. ETFE is available for both Ceres and non-Ceres facilities.

Benefits of ETFE

- 94% UV light transmittance, which can lead to higher yields and improved crop quality

- Fewer pathogens and pests in the grow facility, because of the radiation from the UV light

- High mechanical strength, resistant to high wind and snow loads

- Won’t degrade or yellow, as a result of UV light

- Easy to repair, with use of ETFE glazing patches and sheets

- Recyclable

- Fire Rated ASTM E84 Class A (ETFE foil will shrink from plume, which vents the fire)

- Stable exceeding 400F degrees

- Available in multiple layers

- Diffuse ETFE allows for deep light penetration into the canopy, reducing pruning and trimming labor, and increasing yields

Control & Optimize the Light

Option for diffused light, which allows for the reduction of shadows and thus improved plant growth.

The image on the right shows diffused versus clear glazing and how it affects shading. On the left side of the greenhouse clear ETFE has been used on the south facing windows. Diffuse ETFE was used on the roof, so there is no shading as you travel away from the south facing windows.

Low Maintenance & Design Flexibility

- Durable material resistant to all environmental conditions, including hail

- Does not degrade- long lasting

- Design flexibility and lightweight

Energy Savings

- Additional thermal insulation provided by multilayer glazing options

Greenhouse Technology

Supplemental lighting is required to optimize plant growth, plant quality and ultimately profits in low light conditions such as mornings/evenings, winter days with low light levels, and cloudy days.

One centralized system for controlling the whole environment. Monitor temperature, relative humidity, and CO2, leaf/ canopy temp, PAR, lighting zones, and outdoor weather.

Unlike most other grow facilities, at Ceres we integrate a water recapture & filtration system in every greenhouse, Recapture and filtration not only increase efficiency, it also saves money, especially in places where water is scarce.

Grow the highest quality crop with full UV transmission. ETFE is durable and easy to repair. It allows all of the benefits of an outdoor grow, while still maintaining complete environmental control with in the facility.

Ceres fully automated light deprivation greenhouses allow for total control of light levels in your commercial or medical cannabis facility. Light deprivation is a necessary component of an automated cannabis greenhouse and is available in every size and model.

Explore our proprietary HVAC, dehumidification, and humidification (fogging) systems. We offer everything from a la carte systems for retrofits, to fully integrated geothermal HVAC solutions for new builds. Learn more about our GAHT®, EcoLoop™, and EcoPack™ system options.

Access Cannabis Brochures

Calculate Your Energy Savings

Find out how much you can save with Ceres Greenhouses compared to standard greenhouses.

Related Webinars, Videos and Content

ETFE FAQs

Ceres’ ETFE is a unique glazing material for greenhouses because it allows for the penetration of full spectrum light, thereby allowing the plants in a greenhouse to grow under the same light conditions as they would do outdoors. With diffuse ETFE the light conditions in the greenhouse are even better than they would be outdoors, as the plants receive even more light.

Because ETFE is UV transmissive, plants are able to create higher levels of terpenes (flavors, colors, and smells) as compared to polycarbonates (and most types of glass). UV light also helps reduce pests and pathogens in the greenhouse environment.

The ETFE roof and wall systems are the longest lasting glazing systems (greenhouses already in operation for 40 years and more in Europe) and require very little maintenance. Occasional cleaning with water may be recommended depending on the location and degree of dust accumulation.

ETFE is the most hail resistant glazing material (that also has full light spectrum transmission), the most seismic activity resistant, and the most fire rated glazing material as well.

ETFE film is priced by its thickness and type (diffuse or clear). Film thickness varies in practical applications from as low as 60um for internal walls, to over 300um for the highest hail size and snow/wind loads. The thinner ETFE film prices are comparable to double layer polycarbonate.

Diffuse ETFE glazing is also available with an anti-drip coating, to ensure that condensation on the ETFE does not drip onto the plants. The anti-drip coatings increase the price by about 30%.

Ceres offers a completely engineered and engineer stamped roofing solution. This service includes engineering, aluminum fastening tracks, hardware such as fasteners, and installation instructions.

ETFE is a great option for a greenhouse glazing material where the fire code requires the highest fire rated material, when there is earthquake potential, or when high resistance to hail, wind and snow loads are required.

ETFE may also be a great option for complex building forms.

If you are interested in a long-term solution, ETFE is a better option, as it does not require replacement nearly as often.

As ETFE is UV light transmissive, it is the better option if the quality of the crop is important.

ETFE offers an almost unlimited service life. Greenhouses that have had ETFE installed in the early 1980’s have been in continuous operation ever since. ETFE will last longer than any other plastic glazing material and is comparable with glass in its lifespan. ETFE can be completely recycled if it is no longer needed.

The films come with a 10 year warranty from the manufacturer. It should be noted that the warranty does not suggest that the film or the anti-drip coating will diminish in quality over time.

ETFE is not brittle like Acrylic, Glass or Polycarbonate. A variety of independent lab tests have shown that ETFE films, with a thickness of 250um, can withstand hail with 2 inches (50 mm) and more –causing only indentations in the ETFE glazing. ETFE films are classified Hail class 3. In most cases, any hail caused indentations in the ETFE can be repaired with a thermal gun ( i.e hair dryer) or ETFE repair tape without losing its quality and characteristics.

Acrylic sheets are warranted up to ¾” (20 mm). Hail above that size will cause acrylic sheets to break. Thick 3 layer polycarbonate will suffer irreparable indentions.

ETFE can be installed on any greenhouse, such as rectangular (greenhouse) buildings with standard roofs (glass or plastic), center gable or off-set gable, hoop houses, chinese style greenhouses, custom greenhouses, etc. When in doubt, contact us to find out if ETFE is the best solution for your new or existing greenhouse.

The track system that allows for the proper installation of the ETFE film on greenhouses was designed by Ceres and its exclusive partners. It is part of Ceres’ Intellectual Property. Currently Ceres is the only greenhouse company in the world to offer a comprehensive engineered multi-layer solution for ETFE on greenhouses.

The number of layers will vary regionally, and depends on the level of insulation desired. Contact us for more information.

ETFE is an electronegative, hydrophobic (does not like water) material. Fine dust can stick to the surface of the ETFE both from the outside and inside of the greenhouse. Since ETFE does not ‘like’ water, any dust collecting on the ETFE surface will accumulate in any water droplet that hits the ETFE surface. As a result, ETFE is highly cleanable with water. For the outside layer, rain is sufficient for cleaning itself. If extra cleaning is required, common household cleaners can be used to clean the surface without any problems.

ETFE is hydrophobic (does not like water or ice) and therefore snow will glide off the roof easily as long as the roof slope is appropriate. The Ceres’ ETFE system is not recommended for flat roofs.

Walking on ETFE sheets itself is not recommended. Most ETFE professional contractors/roofers choose to walk on scaffolding that is securely laid perpendicular to the ETFE track systems.

Ceres cannot be held responsible for accidents during installation. We recommend using professional installers for installations above ground level.

Greenhouses can have a reputation of being ‘leaky’. This is because there are many interfaces between different materials that are hard to seal. One of the biggest advantages of using ETFE is that it can be installed over large areas without a single seam. As a result, greenhouses built with ETFE can be much tighter than greenhouses built with any other glazing material.

ETFE systems (ETFE and Aluminum) are the highest temperature rated roof covering. Temperatures in excess of 400F (200C) do not harm the ETFE, or the system that was used to install it. No other roofing system can withstand such temperatures.

Polycarbonate is rated up to 280F (140C) and Acrylic is rated for up to 200F (90C) but can deform at temperatures as low as 160F (70C). Glass can be rated at a higher temperature itself, but the polymers used to install and seal the glass have lower temperature ratings.

ETFE needs to be pre-tensioned to withstand wind, hail and snow. In non-inflated greenhouses, the correct pre-tension can only be set in relatively warm temperatures, ideally as warm as possible, but temperatures for the ETFE during installation must be above 50F (10C). In some cases, the temperature of the ETFE can be increased by installing heaters inside the greenhouse space during installation. If the temperature is too low during installation, on warm summer days the ETFE will expand enough to lower the pre-tension of the ETFE below the recommended values. As a result, the ETFE could sag a bit in very hot temperatures. This effect is an aesthetic concern, not a safety concern.

In double layer, inflated hoop houses, this tension is provided by a fan keeping the 2 films at the correct pressure all year at any temperature. Therefore, ETFE can be installed anytime.

ETFE films are a universally used covering for all kinds of buildings. Small greenhouses of less than 100 sq ft (10m2) can be as easily covered, as whole football stadiums like SOFI stadium in Los Angeles, or the million sq ft Allianz Arena in Munich, Germany (100,000m2 and more). In addition, ETFE can be used for all buildings where complex building forms or shapes are desired.

During temperature swings from -40F to 120F (-40C to 50C), the expansion and contraction of different materials varies significantly. ETFE, aluminum track systems, steel, and wood support structures all have different rates of expansion with temperature. The Ceres team considers the effects of these differences in their design and will suggest installation guidelines on how to install the ETFE system accordingly.

The infrared radiation reflection of ETFE is 35000 nm and above (ultra long wave infrared radiation) during the night, keeping the plants warmer even on clear nights.

Permits for re-roofing/glazing any structure may or may not be necessary. Unless otherwise specified, it is the responsibility of the client or clients’ architect to verify that any regulations are met.

Ceres and/or the stamping engineer can provide most of the technical documents necessary to obtain the permit. Depending on the requirements from the building department (extra fee may be necessary).

With every project in which Ceres provides a fully designed ETFE system, Ceres will provide drawings that show the necessary parts to install the ETFE properly. Depending on the customer requirements Ceres may or may not show all flashing details. When ETFE is installed on existing greenhouses, the client will be responsible for the accuracy of the drawings of the existing building.

Usually, no drawings are provided with ETFE film only orders unless requested.

ETFE is a rather forgiving material and depending on the structure can be installed by almost any skilled laborer. For small structures, ETFE can be installed by the homeowner, with a minimum of 2 people required. In larger structures, movement on the roof requires skills and safety equipment that usually require professionals with the right equipment. These can be roofers or general contractors. Teams of 4 or 5 people are recommended.

In general, contractors unfamiliar with ETFE installations will quote high installation costs because of the unknowns about the process. Ceres experts will be available to answer questions during the quoting process. Furthermore, Ceres recommends that clients and/or their contractors come to see an existing installation in Boulder, CO to familiarize themselves with the process. Ceres can provide references for skilled contractors for any installation.

Greenhouse specific ETFE films can be delivered within a 4 week timeframe.

Depending on the size of the greenhouse, the film thickness, the hardware required, and inventory levels, delivery of materials can take up to several months.

Greenhouse ETFE distinguishes itself from conventional ETFE because greenhouses with high moisture levels require an anti-drip coating on the inside layer of the ETFE that will prevent or at least significantly reduce the water dripping onto the plants. This drip water can cause powdery mildew and similar diseases.

ETFE with an anti-drip coating is very hard to weld into large sheets, and as far as we know, Ceres is the only company in the world that can offer large ETFE sheets with anti-drip coatings in all common thicknesses.

ETFE films can be diffused or clear and Ceres will help select the best grade for each specific project application. Clear films are better when visibility into or out of the greenhouse is desired. Diffused films are better for the plants because they scatter the sunlight onto the plant, diminishing pests, increasing photosynthesis and contributing to the overall health of the plant.

ETFE films are available in 50um, 60um, 100um, 150um, 200um, 250um and more. In general, the thicker the material, the higher the hail, wind and snow resistance, the wider the track spacing and the lower the light transmission. For example, with 250um the light transmission is 87% whereas with 100um the light transmission is 94%. While thicker films reduce the light transmission slightly, the increased distance of the support structure will allow for more sunlight coming into the greenhouse ,which will offset that loss. Due to minimum order quantities, Ceres is mainly working with 50um, 60um, 100um and 250um thicknesses.

Increasingly, plastics are becoming the most common glazing material for greenhouses. This is mostly due to the extreme weather conditions including large hail, very high wind, high seismic activity and extreme snow loads.

Amongst plastics, ETFE has the advantage that is not only the most weather resistant material but also the most lightweight greenhouse covering. This allows our engineers to design support structures that are more lightweight and therefore more light transmittance.