The controlled environment agriculture (CEA) industry is steadily advancing every day, especially in the fields of greenhouse automation and control systems. Growers are integrating different technologies that are helping them to improve plant health, boost yields and be more energy-efficient. In this article we will give an overview on greenhouse automation and also provide five major benefits of these technologies for commercial cannabis greenhouse owners and/or growers.

What is automation in greenhouses?

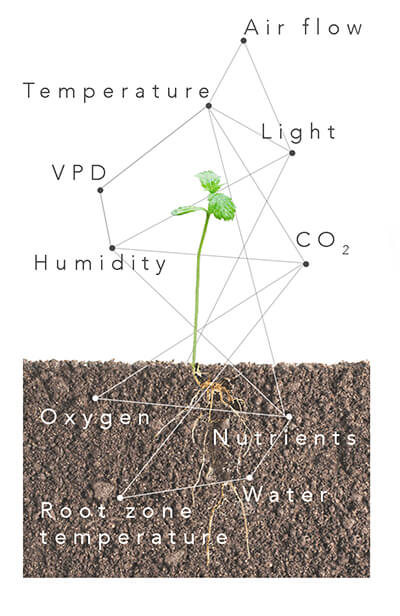

Automation in greenhouses refers to using technology to control and monitor various aspects of the greenhouse environment and growing process. Automation systems can regulate temperature, humidity, lighting, watering, and other factors that affect plant growth. Automation systems can also monitor and control the delivery of nutrients, pesticides, and other substances to plants.

Cultivars can use automation in greenhouses to optimize the growing environment, ensuring that plants receive the proper amount of light, water, and nutrients. Automation can help improve the greenhouse operation’s efficiency and productivity, leading to healthier plants and higher yields. Automation can also help reduce labor costs, as many tasks can be automated, improving the consistency and quality of the plants being grown.

Many types of automation systems and technologies are available for greenhouses, and they will usually include computerized control systems, sensors, and intelligent irrigation systems (automation that controls drippers into the plants etc.). The specific automation technologies used in a greenhouse will depend on the needs and goals of the operation.

How does greenhouse automation work?

Greenhouse automation typically involves computerized control systems and sensors to monitor and control various aspects of the greenhouse environment and growing process. These systems can be programmed to regulate temperature, humidity, lighting, fertigation, and other factors that affect plant growth.

Greenhouse automation typically involves computerized control systems and sensors to monitor and control various aspects of the greenhouse environment and growing process. These systems can be programmed to regulate temperature, humidity, lighting, fertigation, and other factors that affect plant growth.

For example, a greenhouse automation system might include sensors that measure the greenhouse’s temperature, humidity, and light levels. The system might also include controllers that can adjust the temperature, humidity, and lighting in the greenhouse based on the readings from the sensors. The system might also include irrigation controllers that can turn watering systems on and off based on the moisture levels in the soil.

In addition to controlling the greenhouse’s physical environment, automation systems are used to monitor and control the delivery of nutrients, pesticides, and other substances to plants. This is done using specialized equipment, such as nutrient delivery systems and sprayers.

At Ceres, we have developed our own automated greenhouse controller called the SunSense™. With a SunSense™ controller, growers can optimize environmental parameters by programming environmental recipes specific to different stages of plant growth. With the SunSense™, we make it easier for growers to achieve ideal temperature and humidity levels by allowing them to enter vapor pressure deficit (VPD) set points into the interface. The controller also monitors and controls DLI and PPFD light levels and CO2. The SunSense™ dashboard can be accessed remotely so that you can monitor and adjust your facility from anywhere.

Now that you know what a SunSense™ does, let’s discuss how this helps you as a grower or greenhouse operator.

What are five advantages of the SunSense™ automated controller?

There are several advantages to using SunSense™ automated controllers in greenhouses and other agricultural settings:

- Increased efficiency: SunSense™ automated controllers can help to optimize the growing environment, ensuring that plants receive proper amounts of light, water, and nutrients leading to healthier plants and higher yields.

- Reduced labor costs: SunSense™ automated controllers can help to reduce the amount of labor required to run a greenhouse or agricultural operation, as many tasks can be automated. This can help to lower labor costs in greenhouses and increase profitability.

- Improved consistency and quality: SunSense™ automated controllers can help maintain consistent growing conditions, leading to more consistent growth and high-quality plants or crops.

- Enhanced monitoring and control: SunSense™ automated controllers can help to improve the monitoring and management of the growing environment, allowing growers to make more informed decisions and take a more proactive approach to manage their operations.

- Increased safety: SunSense™ automated controllers can reduce the risk of accidents and injuries in the greenhouse, as many tasks can be automated and performed remotely.

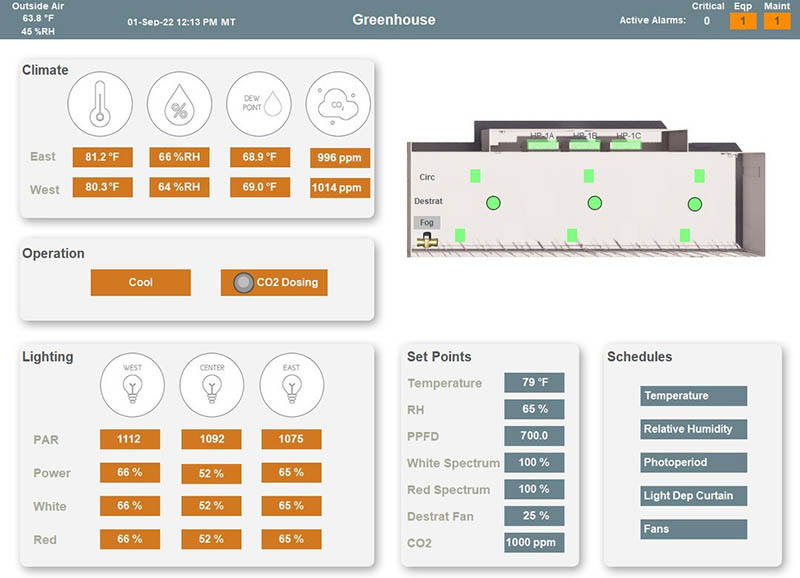

Here is an example of a SunSense™ controller interface for a flowering cannabis greenhouse. Across the upper section we see actual conditions in the greenhouse. We can see which operations are running at the moment (cooling only), and we can see the set points that the cultivator has requested.

Looking at the data we can learn about what’s happening outside. For instance, at 1000 PPFD in the greenhouse, with the lights only running at 60%, we can infer it’s a partly cloudy day. The LEDs have dimmed up to 60% to which probably means it was just cloudy but the sun has come out somewhat, which is why the light level is over the lighting set point.

Looking at the data we can learn about what’s happening outside. For instance, at 1000 PPFD in the greenhouse, with the lights only running at 60%, we can infer it’s a partly cloudy day. The LEDs have dimmed up to 60% to which probably means it was just cloudy but the sun has come out somewhat, which is why the light level is over the lighting set point.

On the lower right of the screen you can see the scheduling function, which allows cultivators to set a schedule for how they want the greenhouse to perform over the week or month.

Is it time to upgrade your facility?

There are many benefits of installing a greenhouse controller in your facility, but the biggest takeaway is that this technology will save you money (on labor and energy costs) while significantly increasing your yields. If you are interested in learning more about the SunSense™, or would like to speak to a greenhouse expert, contact us today!