At Ceres we are challenging the idea that “high tech” means “expensive” when it comes to greenhouse design. Between our patented passive solar structural design and our Ground to Air Heat Transfer (GAHT®) System, innovation is at our core and we aim to provide growers with the most energy-efficient growing solutions. We help our growers achieve the most productive growing environments possible while simultaneously saving them money on operational costs. This year has been a big year in developments for Ceres and we’d like to introduce our newest climate control greenhouse system to date: the Ecoloop™.

Function

The Ceres Ecoloop™ is a ground coupled heat pump system that heats, cools and dehumidifies our sealed greenhouses. It acts as an innovative geothermal HVAC system that utilizes the Earth’s steady temperature (between 45°- 60°F) to create precise climates in each greenhouse environment.

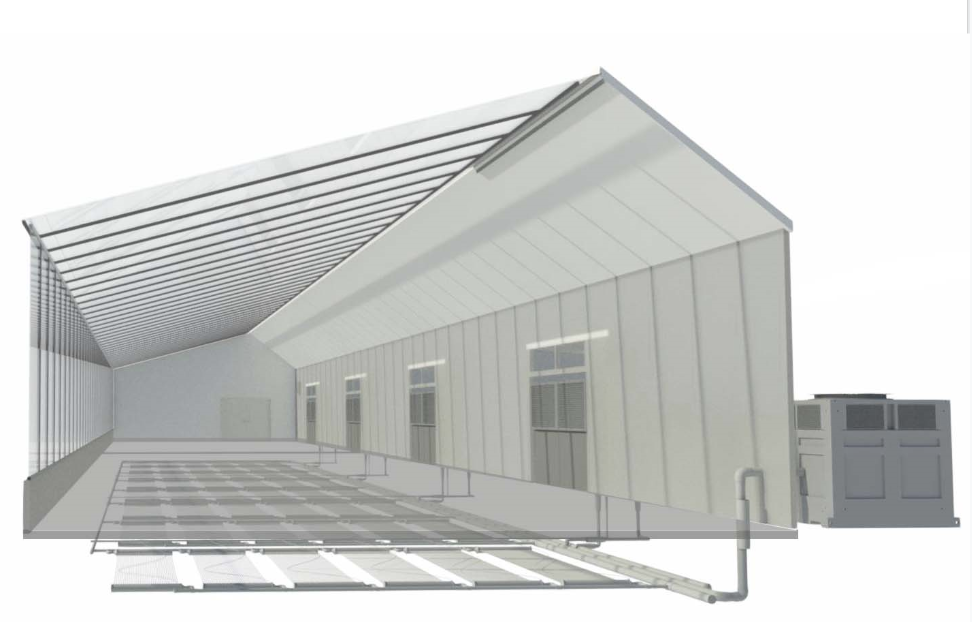

To break it down, the Ecoloop™ is made up of two primary components: a ground source heat pump and a ground loop. The ground source heat pumps are attached to the North wall of the greenhouse, above ground. The pumps filter and condition CO2 rich air from inside the sealed greenhouse environment. The ground loop component transfers thermal energy to or from the greenhouse heat pumps. This is achieved by recirculating water through subsurface piping. The recirculating water will either absorb heat from the ground (Ecoloop™ in heating mode) or disperse heat back into the ground (Ecoloop™ in cooling mode). The two components together make up a completely closed-loop system.

We should probably mention the fluid coolers as they are on the diagram and are an integral part of the GCHP system. The fluid coolers are basically there to add an extra boost of cooling when the ground alone cannot handle the cooling load. The fluid coolers are there to dump excess heat into the air, via evaporative cooling, before it enters the ground to ensure our ground temperature does not increase over time year after year. Basically the fluid coolers are our “Turbo” when we really need it.

Cooling

When the Ecoloop™ is in cooling mode during peak summer months, hot air will enter the heat pumps and refrigerants inside will absorb and transfer heat to the water recirculating underground in the ground loop. The earth surrounding the ground loop acts as a heat sink and will disperse the heat back into the ground. To add an extra boost of cooling on especially hot days, the Ecoloop™ is equipped with fluid coolers to dump excess heat into the outside air via evaporative cooling. This is done before the air enters the ground to ensure the ground temperatures do not increase over time year after year.

When the heat pump is in this cooling mode, it pulls moisture out of the air and this moisture can be collected in a reservoir and used on site for irrigation purposes. In this way the Ecoloop™ is recycling water by taking moisture transpired by the plants, collecting it and then giving it back to the plants at a later time when it is needed.

Heating

When the Ecoloop™ is in heating mode it absorbs heat from the ground through the water recirculating in the ground loop. The heat pumps concentrate and transfer absorbed heat to the air recirculating in the grow environment. The Ecoloop™ also recovers waste heat from the compressors for reheating dehumidified air. Traditionally HVACs need additional energy to reheat dehumidified air to the desired temperature but the Ecoloop™ recycles energy from the heat compressors via heat exchangers. This innovative concept contributes to its low operational costs.

Dehumidification

In most greenhouses, the HVAC and dehumidification systems are two separate entities working together (or sometimes against each other) to create the perfect growing environment. With the Ceres Ecoloop™ we have combined these two systems so growers can easily achieve exact VPD levels. The Ecoloop™ dehumidifies the greenhouse environment by intaking air and cooling it to dew point inside the heat pump. The heat pumps then reheat the air with waste heat recovery to bring the air back to the desired temperature. The system can dehumidify the air down to 40% relative humidity.

Why go with a Ceres Ecoloop™?

Why go with a Ceres Ecoloop™?

The Ecoloop™ is designed exclusively for our sealed HighYield Kit™design and is a perfect solution for growers seeking heightened biosecurity and precise climate control. Also, the Ecoloop™ is designed for all climate zones and can be built in redundancy for modular expansion. And unlike traditional HVAC systems that create unwanted shading, the Ceres Ecoloop™ takes up no room inside the greenhouse which increases the potential for optimal sun harvesting.

The geothermal qualities of the Ecoloop™ classifies it as a renewable energy source and thus qualifies growers for rebate offers from state and utility programs. Ground coupled heat pump systems have a comparable upfront cost to chillers but GCHP system’s life expectancy is longer and its energy consumption is significantly lower.

The Numbers

We crunched the numbers and determined that growers can expect to save more than 60% on energy costs compared to a traditional HVAC system. A traditional HVAC system uses 87.5 kilowatts of energy per square foot per year whereas the Ecoloop™ uses 35 kilowatts. To translate that to dollars, growers will spend about $10.50/ sq ft/ year to use their HVAC system and they could be spending $4.20/ sq ft/ year with the Ecoloop™.

The development of this product forced us to go back to our roots and come up with a solution that would be revolutionary in terms of energy-efficiency but also be simplistic in terms of concept. A smart grow operation starts with smart design. Contact a greenhouse expert today to discuss your energy-efficient greenhouse project.