The following is an edited version of our article on cannabis odor control strategies for grow rooms and commercial greenhouses, published in High Times.

Why is greenhouse odor control important?

Sweet, skunky, minty, fruity… the aroma of cannabis is an essential feature of the crop, and a key indication of characteristics and quality. Cannabis’ odor is created by terpenes, oil-producing compounds that play a major role in its effects. While an essential part of the plant, terpenes create challenges for commercial greenhouse growers. Most municipalities mandate how grow operations handle odors. In urban areas, regulations may prohibit a greenhouse from venting untreated air outside entirely. Because ventilation is the primary way growers control heat and humidity, this introduces a major challenge – often an impediment — for commercial cannabis greenhouses. Home growers, too, typically want to reduce odors to keep their crops discreet. Thus, the need for odor control spans many sectors. From time-tested to cutting-edge, here is a roundup of greenhouse odor control strategies and their best applications.

Carbon Air Filters (The Standard)

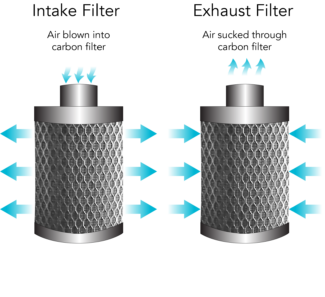

Greenhouse carbon filters for odor control (aka carbon scrubbers) have historically been the go-to method. These use pellets of charcoal to trap terpenes as air passes through the filter. Carbon filters are simple to install, effective and reliable, if changed regularly. The major disadvantage is that they must be replaced frequently, usually every 2-4 months. This is do-able for home growers or small-scale commercial producers, but can get quite costly on larger scales. Although this system is easy to install, it may be impractical for commercial cannabis greenhouses.

If a grower decides to go this route, they would need to install a carbon scrubber in the ducting before air moves through the exhaust fan. Filters should be sized to meet the size of fan (described in cubic feet per minute or CFM).

Air Filters

Air Filters

Standard air filters or air purifiers are densely woven fiber screens. These trap odorous particles as air moves through the filter, which can either be a stand alone unit or incorporated into a ventilation system. These are generally less effective than carbon scrubbers. They are primarily used to remove larger particles like dust and molds from the growing environment. Odor control can be a small or moderate secondary benefit. Advanced ones, like HEPA filters (High-Efficiency Particulate Arrestance) are quite pricey.

Read about sealed greenhouses in our blog, 3 Signs You Should Invest in a Sealed Cannabis Greenhouse.

Odor Neutralizers (For Home Growers)

Odor neutralizers are limited to home growers, as they help cover up the odor, but do not eradicate it. The most common product for cannabis growers is a gel called Ona gel which wafts into the air and binds with terpenes. Be warned, if you use Ona gel improperly in your flowering room, your product could end up smelling and tasting like it. Most growers advise using the gel as a part of the exhaust system so that it’s neutralizing air blowing out of the greenhouse, and no Ona air is coming back in.

Ozone Generators (Not Recommended)

Ozone generators are a longtime tactic to deal with odors, but generally considered risky, and even unsafe. Ozone is a gas that binds with terpenes, but is toxic to both plants and humans in significant concentrations. For those reasons alone, many growers advise against using ozone generators. Others proclaim that they can be used safely because they include controls which make a gas build up less likely. Regardless of how you interpret the research, ozone generators are a less common strategy for those reasons, and one that demands caution for both the grower and the crop for greenhouse odor control.

Biofilters (One to Watch)

Due to the high cost of commercial greenhouse odor control, growers are innovating in the commercial greenhouse space. Tantalus Labs, for example, turned to biofilters as a solution for their cannabis greenhouse. Biofilters — a stockpile of organic material, like wood chips, inoculated with bacteria that naturally consume odorous molecules — have been used for years for livestock operations.

Though this strategy has been proven to reduce methane odors from livestock, Tantalus Labs was the first to evaluate how the bacteria processes terpenes. Their tests showed promise. Currently, the first biofilter application is being used in the company’s 120,000 sq. ft. cannabis greenhouse near Vancouver, Canada.

Another biofiltration process uses chemical reactions, such as a photocatalytic oxidation, to ensure clean air is moving through the growing space. This type of biofiltration is used in conjunction with sealed greenhouses to rid the space of mold, powdery mildew and fungus.

Tantalus Labs’ trial raises an important point. Though greenhouse odor control is not the sexiest topic, it is ripe for innovation. Currently, traditional methods are challenging and costly at scale. That’s why, in this highly regulated industry, growers should take a step back and think about how their greenhouse design can help mitigate odor from the get go. This takes us to our last and most big picture solution – a sealed greenhouse design.

Sealed Greenhouses (For Commercial Growers)

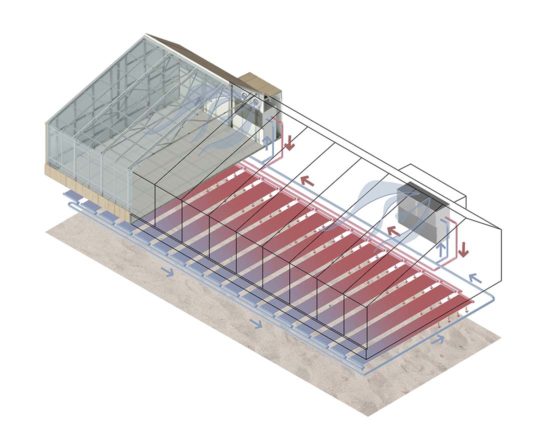

Due to the costs of odor control for large commercial greenhouses, some growers are taking another approach entirely: reducing the need to exhaust air. Instead of exhausting air outside, sealed greenhouses circulate air inside, and use a variety of climate control methods to maintain an optimal indoor environment without ventilation.

This strategy has a number of other benefits: it reduces foreign contaminants, reduces costs from CO2 and energy, and avoids contamination of the crop by hemp pollen (a recent issue in legal states like Colorado). However, enclosing a greenhouse raises other challenges like controlling over-heating and humidity. Companies are quickly responding with innovative climate control solutions to enable an enclosed greenhouse environment. The Ceres SunChamber™, for example, is a greenhouse facility tailored for any climate, because it is a completely sealed solution – giving it the benefit of precise environmental control as well as biosecurity.

This strategy has a number of other benefits: it reduces foreign contaminants, reduces costs from CO2 and energy, and avoids contamination of the crop by hemp pollen (a recent issue in legal states like Colorado). However, enclosing a greenhouse raises other challenges like controlling over-heating and humidity. Companies are quickly responding with innovative climate control solutions to enable an enclosed greenhouse environment. The Ceres SunChamber™, for example, is a greenhouse facility tailored for any climate, because it is a completely sealed solution – giving it the benefit of precise environmental control as well as biosecurity.

A combination of tailored climate control solutions integrated within the SunChamber™ make this possible – including the Ceres EcoLoop™, a geothermal HVACD system that can heat, cool and dehumidify a greenhouse environment.

Creating a super controlled environment with advanced climate controls is a major trend in the cannabis greenhouse industry. It enables growers to keep odorous air inside, while still providing precise environmental control and sufficient air movement. Back-up ventilation systems with carbon scrubbers can be much smaller, allowing for initial and ongoing savings.

You can read more about the pros / cons of a sealed greenhouse in our blog, 3 Signs You Should Invest in a Sealed Cannabis Greenhouse.

Still wondering what odor mitigation solution is right for you and your operation? Ceres greenhouse experts can work with you and your growing goals to figure out the best greenhouse odor control solution for your specific situation.

Contact us today to get in touch!