More and more cannabis cultivators are choosing to grow in greenhouses rather than indoor warehouses in order to cut down on energy costs and utilize the productivity of the sun. This trend, coupled with industry expansion, has led to the emergence of large-scale commercial cannabis greenhouse complexes. Most of the commercial greenhouse complexes built today are gutter-connected structures that house one large grow room or many smaller grow rooms with minimal biosecurity from one to the next. While these behemoth, open-floor, greenhouses can boast huge production numbers from one harvest, the operators run a huge risk of losing entire crops at a time if mold, mildew or pests gain a foothold in the grow room. At Ceres, we take a different approach to commercial cannabis greenhouse design by adopting modular grow solutions for our larger operations. Let us explain why this design is beneficial for increased biosecurity and much more.

Passive Solar and Modular Cannabis Grow Rooms

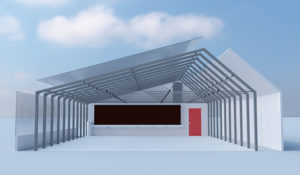

To understand our modular grow solution, you’ll need a quick introduction to our patented passive solar greenhouse design. We build our greenhouses to orient east/west with glazing on the south wall and south-facing roof of the structure. The east, west and north walls and the north-facing roof are constructed with insulated metal panels. This passive solar design allows for light harvesting, which is beneficial for both plant growth and greenhouse energy efficiency.

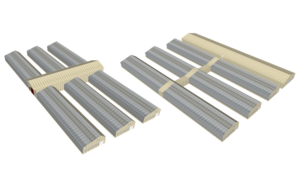

We offer two types of modular layouts for our passive solar greenhouse design. One layout includes greenhouses stemming out on the east and west sides of a central headhouse, that is oriented north/south. In the other layout greenhouses stem from the east and west sides of a central hallway that connects to a headhouse at the northern end of the complex. The type of modular layout depends largely on the land that’s available, type of operation and other client needs.

We offer two types of modular layouts for our passive solar greenhouse design. One layout includes greenhouses stemming out on the east and west sides of a central headhouse, that is oriented north/south. In the other layout greenhouses stem from the east and west sides of a central hallway that connects to a headhouse at the northern end of the complex. The type of modular layout depends largely on the land that’s available, type of operation and other client needs.

So why should you build modular cannabis grow rooms?

Biosecurity

With the modular concept, individual greenhouses are separated by either a sterile hallway or a headhouse. If pests, mildew or mold are discovered in any of the greenhouses it is easy to confine to one house so it doesn’t spread to the others. Modularity allows for more control of contamination and ensures you don’t lose an entire crop at one time.

Individual climates

Separated greenhouses also allow for individualized climates. You can control different environments for every stage of plant growth in order to stagger harvests for higher productivity. Take, for example, our hemp growers at Green Lynx Farms in Mancos, Colorado. They own four individual HighYield™ Kit greenhouses connected to one central headhouse. One of their greenhouses is used for CBD hemp vegetative growth, allowing for higher levels of humidity than their other greenhouses housing more mature plants.

Another benefit of individual greenhouse environments is that you can simulate multiple different climates in order to prepare plants for production in other parts of the world. According to our cannabis designer, Sunny, “This is especially important as the cannabis plant adapts quickly to its environment and expresses unique phenotypes.” In addition, if you are a grower working with cannabis genetics, you can use the modular grow solution to test different growing methods and different climates for optimal strain development.

Business Expansion

Business Expansion

At Ceres we build our greenhouses to grow with your business. Our modular cannabis greenhouse layouts allow for unlimited expansion as your business becomes more successful and you need more grow space. Also, continuous expansion will not interrupt your operation’s workflow as construction can take place while you continue to grow and harvest plants in your other greenhouses.

Green Lynx Farms originally started out with three hybrid, 30’ x 75’ greenhouses in the Spring of 2018. Because they were so successful in their first year of growing in their Ceres greenhouse, they were able to fund the construction of a fourth 30’ x 150’ greenhouse in early 2019. Their headhouse was already framed to accept a fourth building, so simply cutting out the wall allowed for easy connection of the new greenhouse. For more details on this project, watch our Youtube video, Drone Footage of a Ceres Modular Hemp Greenhouse.

At Ceres we strive to be the most innovative in our field by designing highly efficient grow environments catered to your specific growing goals. Deciding to build modular is a strategic business decision that can yield more reward with less risk. If you’d like more information on our HighYield™ modular designs, please contact us! Your success is our success.